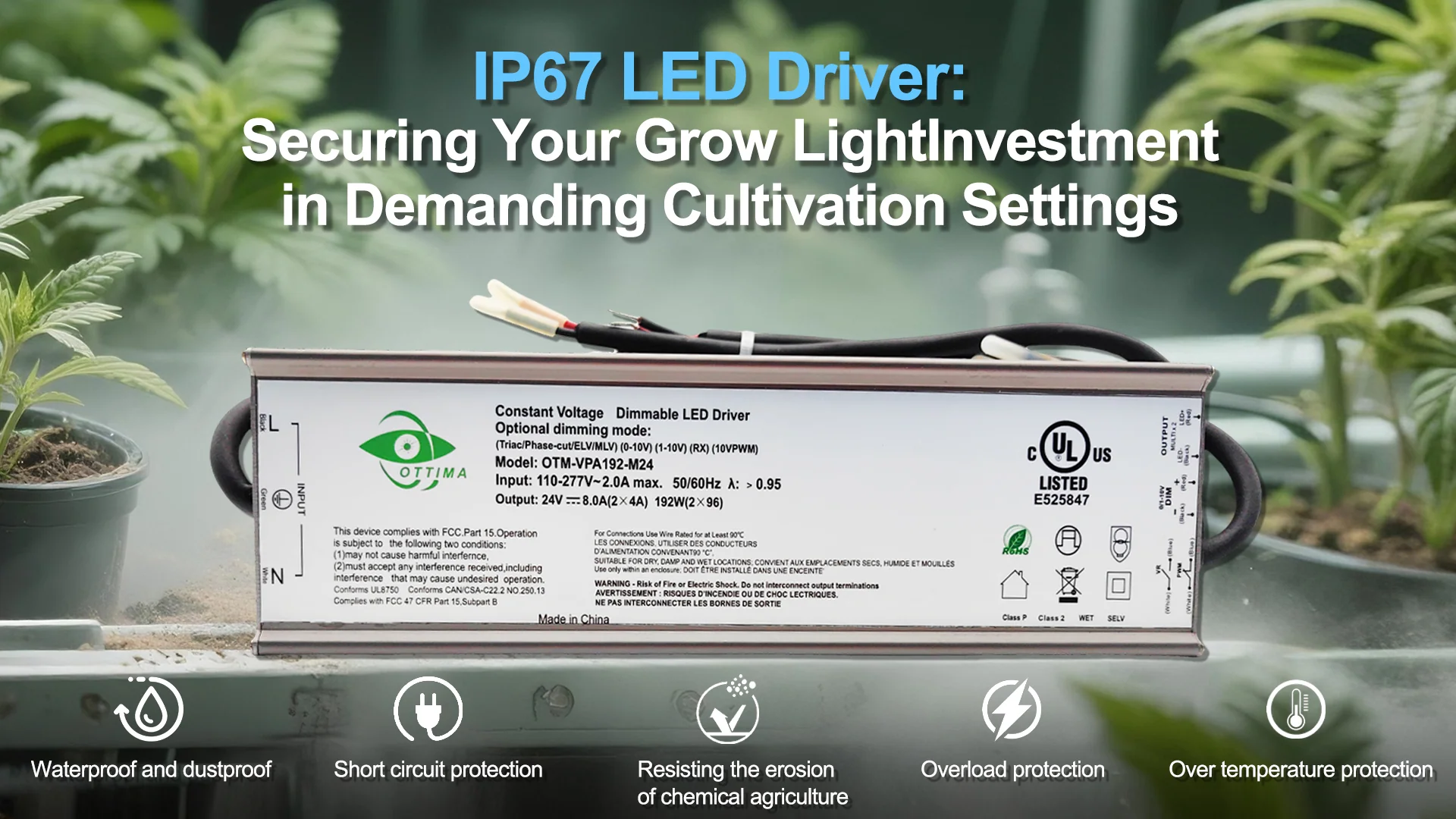

IP67 LED Driver: Securing Your Grow Light Investment in Demanding Cultivation Settings

In the burgeoning world of modern horticulture, LED grow lights stand as a cornerstone of successful cultivation. They offer unprecedented control over light spectrum and intensity, translating directly into optimized plant growth, increased yields, and superior crop quality. Yet, beneath the vibrant glow of a thriving grow room, a critical component often wages a silent battle against its environment: the grow light driver. This essential power supply, representing a significant portion of your grow light investment, is constantly assaulted by conditions that can compromise its integrity and shorten its life.

Standard LED drivers, while perfectly adequate for dry, stable indoor environments, are simply not built for the unique rigors of cultivation. Humidity, water splashes, dust, and even chemical residues are insidious threats that lead to premature failures and substantial financial losses. To truly protect your investment and ensure uninterrupted growth cycles, embracing the IP67 LED driver isn't just an option; it's an absolute necessity.

Why Standard Drivers Fail in Cultivation Settings

Cultivation environments, whether a bustling commercial greenhouse or a meticulously controlled indoor farm, are inherently challenging for electronics. The very conditions optimized for plant life become adversaries for your horticultural LED drivers.

The Pervasive Challenge of Humidity & Water:

Water is everywhere in a grow operation. From automated irrigation systems and routine foliar sprays to the constant transpiration of plants and daily condensation cycles, moisture is an ever-present threat. This moisture can seep into inadequately sealed drivers, leading to:

Corrosion: Oxidizing sensitive internal components and solder joints.

Short Circuits: Water acting as a conductor, bridging electrical paths and causing immediate failure.

Material Degradation: Softening of plastics, swelling of potting compounds, and breakdown of insulation over time.

A corroded PCB trace or a shorted capacitor due to moisture ingress can render an entire grow light system inoperable, halting your cultivation process.

Dust, Dirt & Debris: The Silent Insulators:

Grow rooms are not clean rooms. Airborne particles from growing media (soil, coco coir, rockwool), circulating air, and even dried plant matter can accumulate rapidly. These seemingly innocuous particles wreak havoc by:

Clogging Heat Sinks: Impeding airflow and trapping heat, leading to overheating.

Insulating Components: Forming a layer that prevents efficient heat dissipation from critical electronic parts.

Abrasive Wear: Fine particles can slowly abrade wires and connections.

The result is often accelerated aging of components, reduced efficiency, and ultimately, premature failure of the grow light driver.

Chemical Exposure: A Hidden Corrosive:

Fertilizers, pesticides, fungicides, and even routine cleaning agents are part of daily cultivation. Misted or vaporized, their residues can settle on driver casings and seals. Over time, these chemicals can chemically corrode housing materials, degrade sealing gaskets, and even penetrate the internal circuitry, leading to unexpected failures that are difficult to diagnose.

Heat & Thermal Stress: The Constant Battle:

While LEDs themselves are efficient, they still generate heat, as do their drivers. Combined with the often-elevated ambient temperatures in greenhouses (which can easily reach 30 °C to 40 °C or higher), drivers face significant thermal stress. Sustained high temperatures accelerate the aging process of critical electronic components, particularly electrolytic capacitors. For every 10 °C increase above a component's rated temperature, its lifespan can be halved. This directly translates to a reduced lifespan and increased failure rates for drivers not designed for high-temperature grow light driver operation.

The IP67 Solution: Your Shield Against Environmental Damage

The IP67 LED driver is specifically engineered to combat these relentless environmental threats. IP stands for Ingress Protection, and the two digits quantify the level of protection against solids and liquids.

"6" for Dust-Tight: This means the enclosure is completely protected against dust ingress. No dust particles can enter the driver, preventing the issues of insulation, clogging, and abrasion.

"7" for Temporary Immersion: This signifies protection against the effects of temporary immersion in water, typically up to 1 meter (3.3 feet) for 30 minutes. This level of protection ensures the driver can withstand direct sprays from irrigation, accidental splashes, and even brief submersion without damage.

How IP67 Specifically Protects Your Drivers:

Sealed Enclosures: IP67 LED drivers utilize robust, tightly sealed casings, often made from durable aluminum alloys or specialized plastics. Key sealing methods include:

Potting Compounds: Encapsulating internal components in epoxy or silicone resin, creating an impenetrable barrier against moisture and dust.

Precision Gaskets & O-rings: Used at all seams and cable entries to ensure a watertight and dust-tight seal.

Integrated Cable Glands: Securely sealing the entry points for power and output cables.

Corrosion-Resistant Materials: Components and fasteners are selected for their resistance to corrosion from humidity and common agricultural chemicals, ensuring long-term structural integrity.

Why IP67 is the Baseline: While IP67 is excellent, for truly demanding cultivation settings, it should be considered the minimum standard. Some applications might even warrant IP68 for continuous submersion. Always consult the product datasheet and verify the IP rating through reputable third-party certifications.

Securing Your Investment: Tangible Benefits of IP67 Drivers

Choosing an IP67 horticultural LED driver is a proactive step that yields significant, measurable returns on your grow light investment.

1. Extended Lifespan & Reduced Failures:

By effectively blocking moisture, dust, and chemical ingress, IP67 drivers prevent the most common causes of premature failure in grow rooms. This directly translates to a long life grow light driver.

Quantifiable Impact: In high-humidity environments, non-IP rated drivers might fail within 1-2 years. An IP67-rated driver, however, can easily achieve its designed lifespan of 5-7 years or more.

Example Calculation: Consider a commercial grow operation with 500 LED grow lights, each using a $100 driver. If non-IP67 drivers fail every 2 years ($50,000 replacement cost every 2 years), over 10 years, this means 5 replacement cycles, totaling $250,000 in driver costs alone. With IP67 drivers lasting 5 years, you'd only have 2 replacement cycles, costing $100,000. That's a direct saving of $150,000 on drivers over 10 years, simply by choosing IP67.

2. Minimized Maintenance & Replacement Costs:

Fewer driver failures mean significantly reduced downtime for repairs, less labor cost for swapping out failed units, and less disruption to your cultivation schedule. This contributes directly to reduced maintenance grow lights and a healthier bottom line.

3. Consistent Performance & Yields:

A protected driver maintains stable electrical output, ensuring consistent light delivery (PPF/PPFD) to your plants. Uninterrupted and uniform light cycles are critical for maximizing crop quality, quantity, and achieving predictable harvests. This leads to consistent grow light performance and better overall grow light ROI.

4. Enhanced Safety:

Preventing electrical hazards, such as short circuits and ground faults, in wet and humid environments is paramount. IP67 drivers significantly reduce the risk of electrical shock for personnel and protect valuable property from fire hazards, ensuring a safer cultivation environment.

5. Compliance & Warranty Protection:

Many horticultural lighting standards and even insurance policies implicitly or explicitly require high IP ratings for fixtures used in demanding environments. Choosing IP67 drivers helps ensure your project remains compliant. Furthermore, reputable manufacturers typically offer better and longer warranties on drivers specifically designed and certified for harsh environments, providing an additional layer of protection for your purchase.

Beyond IP67: What Else to Look for in a Horticultural LED Driver

While IP67 is foundational, a truly robust horticultural LED driver offers more than just environmental sealing. To fully secure your investment and maximize performance in demanding cultivation settings, also consider:

Superior Surge Protection: Agricultural grids can be prone to voltage fluctuations and lightning strikes. Look for drivers with integrated surge protection and grow light capabilities, often rated at 6KV/10KV common mode and differential mode, to shield against these electrical assaults.

Wide Operating Temperature Range: Beyond water and dust, extreme heat or cold can degrade performance. A driver with a wide temperature LED driver range (e.g., −40 °C to +60 °C) ensures stable operation regardless of ambient conditions.

High Efficiency: A high-efficiency LED driver generates less internal heat, which further aids its longevity and reduces your electricity bills. This is a win-win for performance and cost savings.

Relevant Certifications: For the North American market, always prioritize UL-certified grow light drivers or ETL-certified products. These third-party certifications provide independent verification of safety, performance, and reliability.

Investing Right, Cultivate Success

The success of your horticultural project hinges on the reliability of every component, and the IP67 LED driver is no exception. It's not just a feature; it's a fundamental requirement for protecting your significant grow light investment in the challenging conditions of modern cultivation. By understanding and prioritizing IP67 protection, alongside other critical features, you are building a lighting system that is not only efficient but also resilient, dependable, and ultimately, more profitable.

Choosing the right, environmentally robust driver is crucial for achieving the long-term reliability, efficiency, and ultimately, the profitability of your cultivation operation.

Ready to elevate your grow operation and secure your investment? Contact us today to explore our range of high-performance, durable IP67 horticultural LED drivers designed to meet the toughest demands of your cultivation settings.