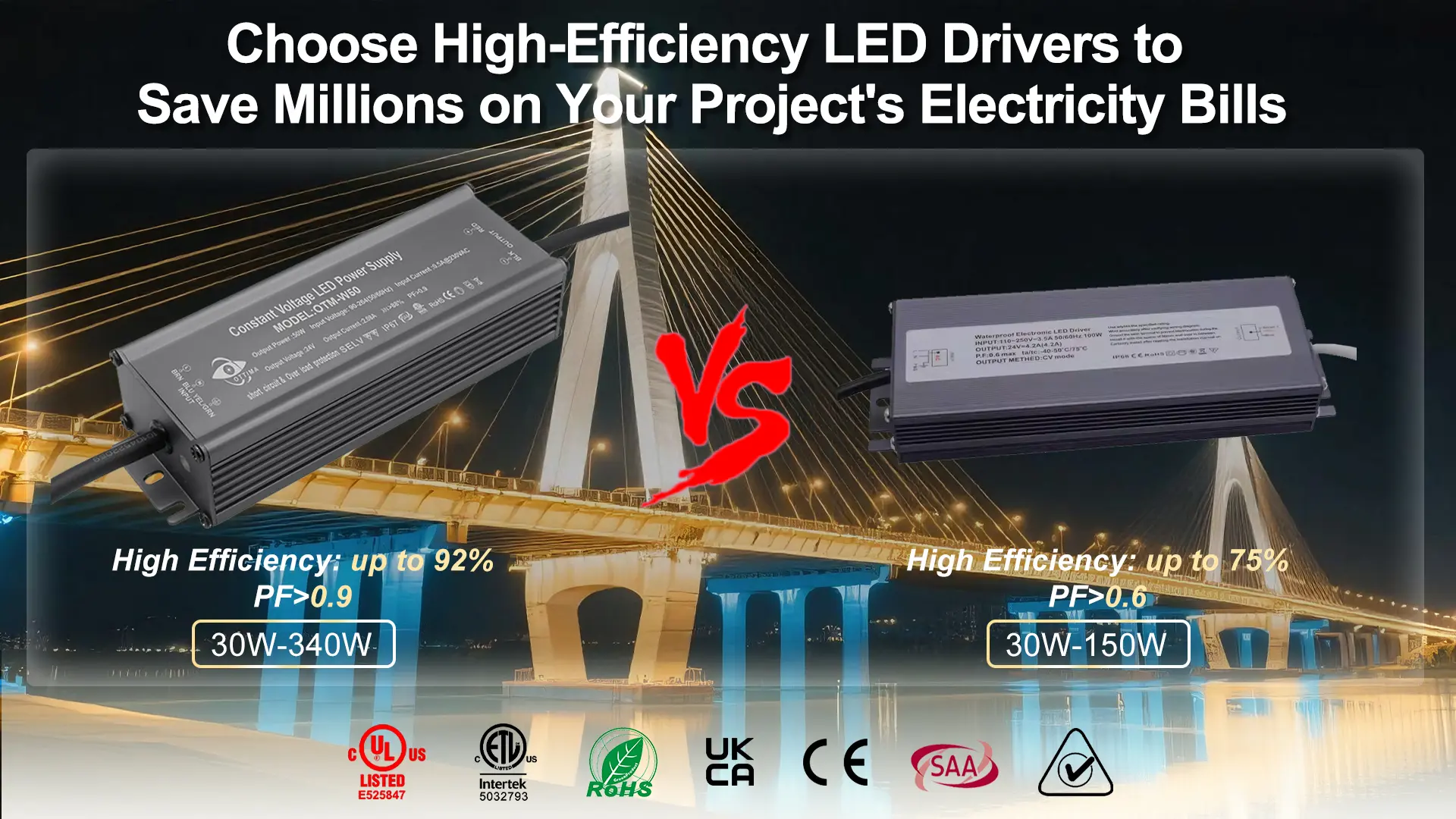

Choose High-Efficiency LED Drivers to Save Millions on Your Project's Electricity Bills

In the realm of modern commercial, industrial, and urban lighting, LED technology has become the undisputed mainstream due to its exceptional energy-saving potential. However, while many project stakeholders rejoice in LED luminaires' energy efficiency, they often overlook a hidden "electricity bill devourer"—the LED driver. As the "heart" of an LED luminaire, the driver's efficiency directly determines the energy utilization rate of the entire lighting system. For large-scale lighting projects involving hundreds or thousands of luminaires, even a minuscule difference in efficiency can accumulate into millions in wasted electricity costs over time.

Today, we will delve into why choosing high-efficiency LED drivers is not merely a technical upgrade, but a crucial strategy to save millions on your project's electricity bills and achieve long-term profitability.

Deep Dive: What is LED Driver Efficiency?

To understand how to save money, we must first grasp what driver efficiency means. Simply put, LED driver efficiency is the percentage of input electrical power (from the grid) that the driver converts into usable output power for the LED chips.

The calculation formula is:

Efficiency(%)= Input Power÷Output Power×100%

This means that if a driver has an efficiency of 90%, for every 100 watts of electrical energy input, only 90 watts are effectively used to illuminate the LEDs, while the remaining 10 watts are dissipated as wasted heat. You, however, still pay for all that wasted energy.

Beyond basic efficiency, two other key indicators cannot be overlooked:

Power Factor (PFC): PFC measures how effectively electrical power is utilized. A high PFC (ideally close to 1) means the current waveform drawn by the driver from the grid is closer to the voltage waveform, reducing reactive power and utilizing grid capacity more efficiently. For commercial and industrial users, a low power factor can lead to additional "reactive power penalties" from utility companies, while high-efficiency LED drivers with high PFC can effectively avoid these extra charges.

Total Harmonic Distortion (THD): THD measures the degree of distortion in the current waveform. A low THD (typically required to be below 10% or 15%) means the driver causes less pollution to the power grid, ensuring stable grid quality and preventing interference with other sensitive electronic equipment. This is also a significant indicator of the quality of LED power supply efficiency.

Inefficient Drivers: Evidence Your Project is "Burning Money"

Now, let's quantify how inefficient drivers can make your project "burn money" with a concrete example.

Hypothetical Scenario:

Your commercial or industrial project plans to install 1,000 LED luminaires.

Each luminaire's LED module requires 100W of power.

The luminaires operate 12 hours per day, 365 days per year.

The local commercial electricity rate is $0.15/kWh.

Comparison:

Driver Type | Efficiency | Input Power per Luminaire (100W Output) | Electricity Consumption per Luminaire per Hour | Electricity Consumption per Luminaire per Year | Total Electricity Bill for 1000 Luminaires per Year |

High-Efficiency Driver | 95%

| 100W/0.95≈105.26W | 0.10526kWh | 459.39kWh | 68,908.50 |

Standard Driver | 88% | 100W/0.88≈113.64W | 0.11364kWh | 497.68kWh | 74,652.00 |

Staggering Electricity Bill Difference:

A mere 7% efficiency difference, for a project scale of 1,000 luminaires, will lead to an annual additional electricity expenditure of:

74,652.00−68,908.50=$5,743.50

This is just for the first year! If your project operates for 10 years, solely due to the driver efficiency difference, you will pay an extra:

$5,743.50×10=$57,435.00

And this is only the direct electricity loss due to efficiency differences. What's worse:

Additional Cooling Costs: The extra heat generated by inefficient drivers increases indoor temperatures, leading to higher air conditioning loads and further pushing up your potential for operational cost savings.

Reduced Equipment Lifespan: Continuous high heat not only wastes energy but also accelerates the aging of the driver itself and the LED chips, shortening the lifespan of the entire lighting system and increasing replacement and maintenance frequency and costs.

Inefficient drivers are indeed a hidden giant in your project's costs, silently "burning" your profits.

Core Features and Technical Advantages of High-Efficiency LED Drivers

High-efficiency LED drivers are not accidental. They are the culmination of advanced technology, precise design, and high-quality materials, aimed at converting every watt of electrical energy into effective light output.

Advanced Topology and Design: High-efficiency drivers typically employ more sophisticated circuit topologies, such as LLC resonant and interleaved PFC, which minimize energy losses during the conversion process.

High-Quality Components: They utilize low-loss, high-voltage, and long-life key components like capacitors, MOSFETs, and diodes. These components maintain stable performance even under extreme conditions, reducing their energy consumption.

Superior Thermal Management: The internal thermal design of the driver is crucial. Through optimized heat sinks, thermal materials, and casing designs, high-efficiency drivers can rapidly dissipate the small amount of heat generated internally, ensuring components operate at optimal temperatures, thereby maintaining high efficiency and extending lifespan.

Smart Control and Dimming: Many high-efficiency LED drivers also integrate advanced dimming technologies (such as 0-10V, DALI, PWM). More importantly, they can maintain high efficiency even at different dimming levels, avoiding sharp drops in efficiency at lower brightness.

Compliance with International Standards: International certifications such as ENERGY STAR and DLC (DesignLights Consortium) inherently impose strict requirements on the efficiency and power factor of lighting products. Choosing certified LED drivers that comply with these standards is a strong guarantee of efficiency and quality.

More Than Just Savings: Other Values of High-Efficiency Drivers

The benefits of choosing high-efficiency LED drivers extend far beyond electricity bill savings. It's a multi-faceted investment that brings broader value to your project:

Extended Luminaire Lifespan: Reduced heat generation from the driver means less thermal stress on its internal components and the driven LED chips, thereby significantly extending the lifespan of the entire lighting system.

Enhanced System Stability: Optimized design and high-quality components lead to more stable output, reduced failure rates, lower maintenance frequency, and guaranteed continuous operation of the lighting system.

Reduced Carbon Emissions: Lower energy consumption directly translates to less electricity usage, thereby reducing carbon emissions from power generation, contributing to your company's sustainable development and environmental image.

Compliance with Regulations: Many regions and countries, especially in the North American market, have mandatory requirements for the efficiency and power factor of commercial and industrial lighting products. Choosing high-efficiency drivers ensures your project complies with these regulations, avoiding potential compliance risks.

Enhanced Brand Image: Adopting energy-efficient and environmentally friendly high-efficiency lighting solutions not only brings tangible economic benefits to customers but also enhances your company's professionalism and social responsibility in the industry.

How to Choose Truly High-Efficiency LED Drivers for Your Project

Faced with a dazzling array of products on the market, how do you identify and choose truly high-efficiency LED drivers?

Review Product Specifications: This is the most direct approach. Pay close attention to the driver's efficiency curve (performance at different loads), Power Factor (PFC), and Total Harmonic Distortion (THD) data. A responsible manufacturer will provide detailed and transparent data.

Look for Certification Marks: Seek out authoritative third-party certifications such as ENERGY STAR, DLC, UL, and ETL. These certifications are strong evidence that the product has undergone rigorous testing and meets specific performance and safety standards.

Consider Actual Application Scenarios: Based on the ambient temperature of your project location, dimming requirements, and dimming precision, choose the most suitable efficiency level and functions. For example, in high-temperature environments, even if the nominal efficiency is high, actual efficiency might decrease if thermal management is poor.

Evaluate Manufacturer Strength: Choose LED power supply suppliers with strong R&D capabilities, rich manufacturing experience, and a good market reputation. They typically have more mature technologies and stricter quality control systems.

Request Test Reports: If necessary, you can ask the manufacturer to provide efficiency test reports issued by authoritative third-party organizations to verify the claimed performance data.

Smart Investment, Continuous Profitability

Choosing high-efficiency LED drivers is key to achieving millions in electricity bill savings for your lighting project, boosting LED ROI, and ensuring long-term stable operation. This is not just about component selection; it's about a thoughtful consideration of future operating costs, environmental responsibility, and project success rates. Now is the opportune time to upgrade your lighting system and embrace high-efficiency driver technology.

Ready to embark on your energy-saving and profitability journey? Contact us today to get customized energy-saving LED driver solutions, and let's illuminate a more efficient, greener future together!