Why Do LED Drivers Dare to Promise a Long Warranty?

In the world of LED driver procurement, the warranty period is a critical indicator. When faced with a driver that promises a five, seven, or even ten-year warranty, a question arisest principles allow a manufacturer to make such a long-term commitment?

This is far from a simple marketing slogan. As a manufacturer with years of experience in this industry, I can tell you that the confidence behind a long warranty comes from a deep understanding and practice of a core philosophy: we are not just manufacturing products; we are actively managing their "failure."

The long lifespan of a high-quality LED driver is not a matter of chance; it is built upon the rigorous application of three core principles.

Derating Design: Engineering for a World Beyond "Limits"

There is a counterintuitive truth in the world of LED drivers: a product operating at full load is often unreliable.

We all want to maximize performance, but in the philosophy of reliability engineering, this is precisely the greatest risk. The core of Derating Design is to ensure that every key component of the product operates at a level far below its maximum rated capacity. This is like setting a reasonable training intensity for an athlete instead of pushing them to their limits every day, to ensure the longevity of their career.

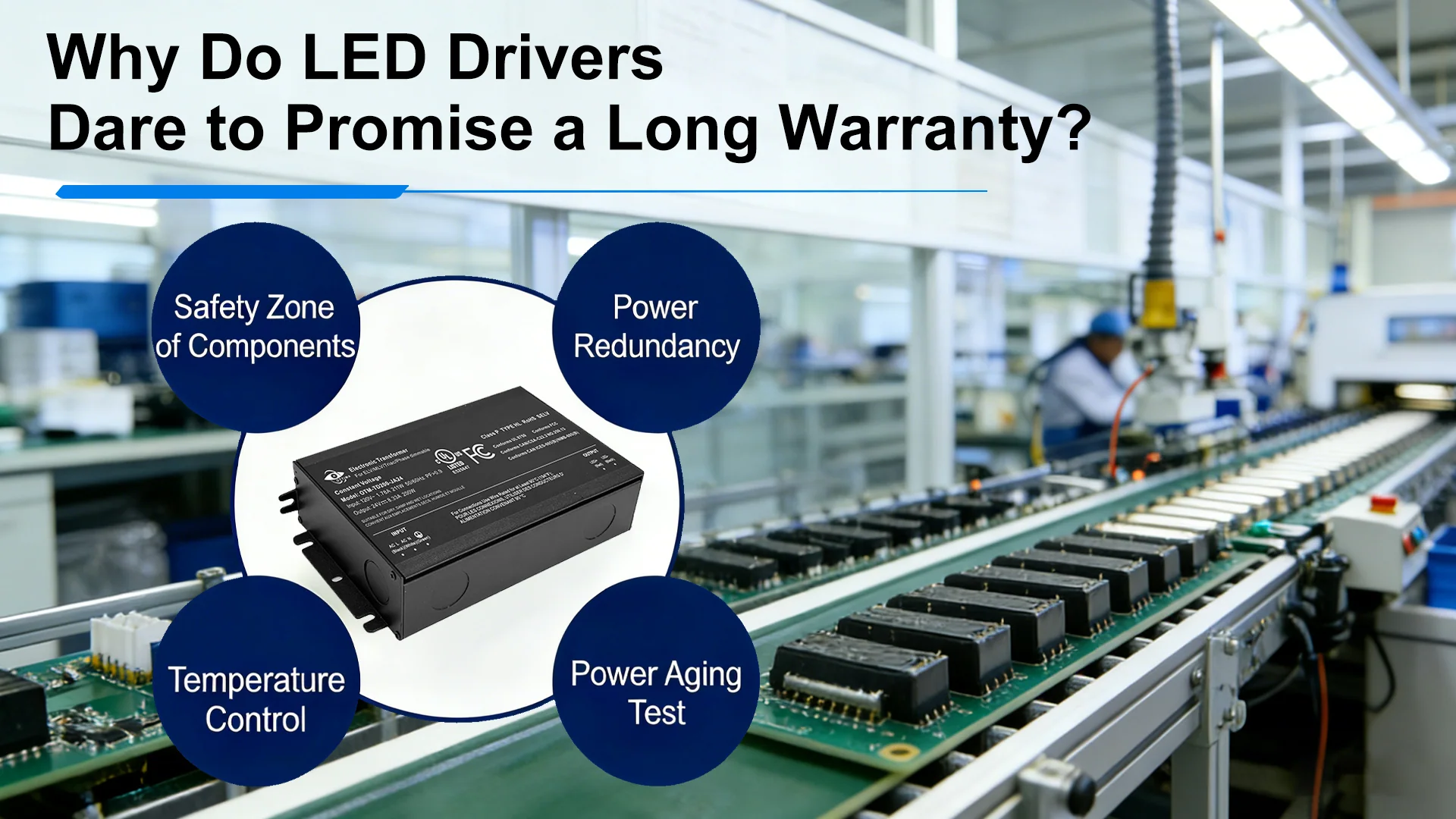

How do we implement Derating Design?

The "Safety Zone" of Components: Every electronic component, be it an electrolytic capacitor, a main control chip, or a MOSFET, has a maximum rating. For example, a capacitor rated for 400V will be operated at 300V or even less. A MOSFET rated for a maximum current of 5A will only be allowed to carry 3A in the circuit. This "sacrificed" margin is the driver's safety cushion against voltage fluctuations, temperature changes, and transient surges.

Power "Redundancy": If a lighting project's theoretical power requirement is 80W, we would never recommend a driver rated at exactly 80W. Instead, we would recommend a 100W or 120W driver. This 20-30% of power "headroom" ensures the driver never operates at full capacity, effectively reducing internal heat and component stress, and minimizing the aging rate.

Derating Design is a strategic compromise that sacrifices "peak performance" on paper for "ultimate reliability" in the real world.

Thermal Management: Keeping the "Lifespan Killer" at Bay

In the electronics industry, high temperature is a well-known "lifespan killer." It not only accelerates component aging but also directly impacts the product's performance and stability.

A high-quality LED driver's thermal management capabilities are the foundation of its long warranty promise. This is more than just adding a heat sink; it's a complete and complex system of engineering.

Controlling Internal Heat Sources: The first step of thermal management is not to dissipate heat, but to reduce it at the source. This involves selecting high-efficiency IC chips and optimizing circuit topology to minimize energy loss during conversion, thereby reducing heat generation.

The Art of External Heat Dissipation: Once heat is generated, how do we efficiently remove it?

Thermal Path Optimization: Engineers design an optimal heat transfer path, like planning a highway network, to ensure heat is quickly conducted from core components (like the main IC and electrolytic capacitors) to the casing.

Unique Potting Compound: Potting is not just for waterproofing and dust protection. A high-quality thermal potting compound can uniformly transfer heat from components to the casing, ensuring an even internal temperature. It's like giving the components a thermally conductive "protective coat," preventing heat from building up in localized areas.

Capacitor "Temperature Control": Of all components, the lifespan of electrolytic capacitors is most closely tied to temperature. An excellent driver's internal layout ensures that electrolytic capacitors are positioned away from major heat sources, and a clever thermal path design keeps their operating temperature below 85 ℃ or even 65 ℃, significantly extending their life.

Thermal management is a form of "life support" that provides the driver with a cool and stable operating environment, allowing it to "live longer."

Lifetime Testing: Using Data to Predict the Future

A warranty promise is not based on guesswork; it's based on thousands or even tens of thousands of hours of rigorous testing. This is like putting a product through a "miniature lifetime" to predict its long-term performance in the real world.

Accelerated Life Testing (HALT/HASS): This is the most crucial testing phase. We subject drivers to extreme conditions, such as high and low temperature cycling, high humidity, vibration, and sudden voltage changes, to observe their performance. By doing so, we can quickly uncover potential weaknesses and predict the product's long-term behavior in a compressed timeframe.

Rigorous MTBF Calculation: Based on the data from accelerated life testing, we use reliability engineering and statistical principles to accurately calculate the product's MTBF (Mean Time Between Failures). This number is not a guess; it's a rigorous prediction based on scientific data and failure models. When a driver has an MTBF of 200,000 hours, it means that, statistically, it is expected to operate without failure for over 20 years under normal working conditions.

Lifetime testing is a "data-driven" promise that provides the most solid scientific foundation for our warranty commitment.

The True Meaning of Warranty is Creating Long-Term Value for Your Project

Friends, when you see an LED driver that promises a long warranty, don't just look at the price difference.

Behind that promise is a manufacturer's commitment to derating design, mastery of thermal management, and investment in rigorous testing.

Derating design provides you with a margin of error, making your project resilient to environmental changes.

Thermal management ensures the product's longevity, saving you from high future maintenance costs.

Lifetime testing provides data-backed trust, giving you confidence in the long-term stable operation of your project.

Choosing a high-quality driver is not "spending more money"; it's the most prudent investment in your project's long-term value and brand reputation. We believe that a reliable driver is the cornerstone of your successful business.