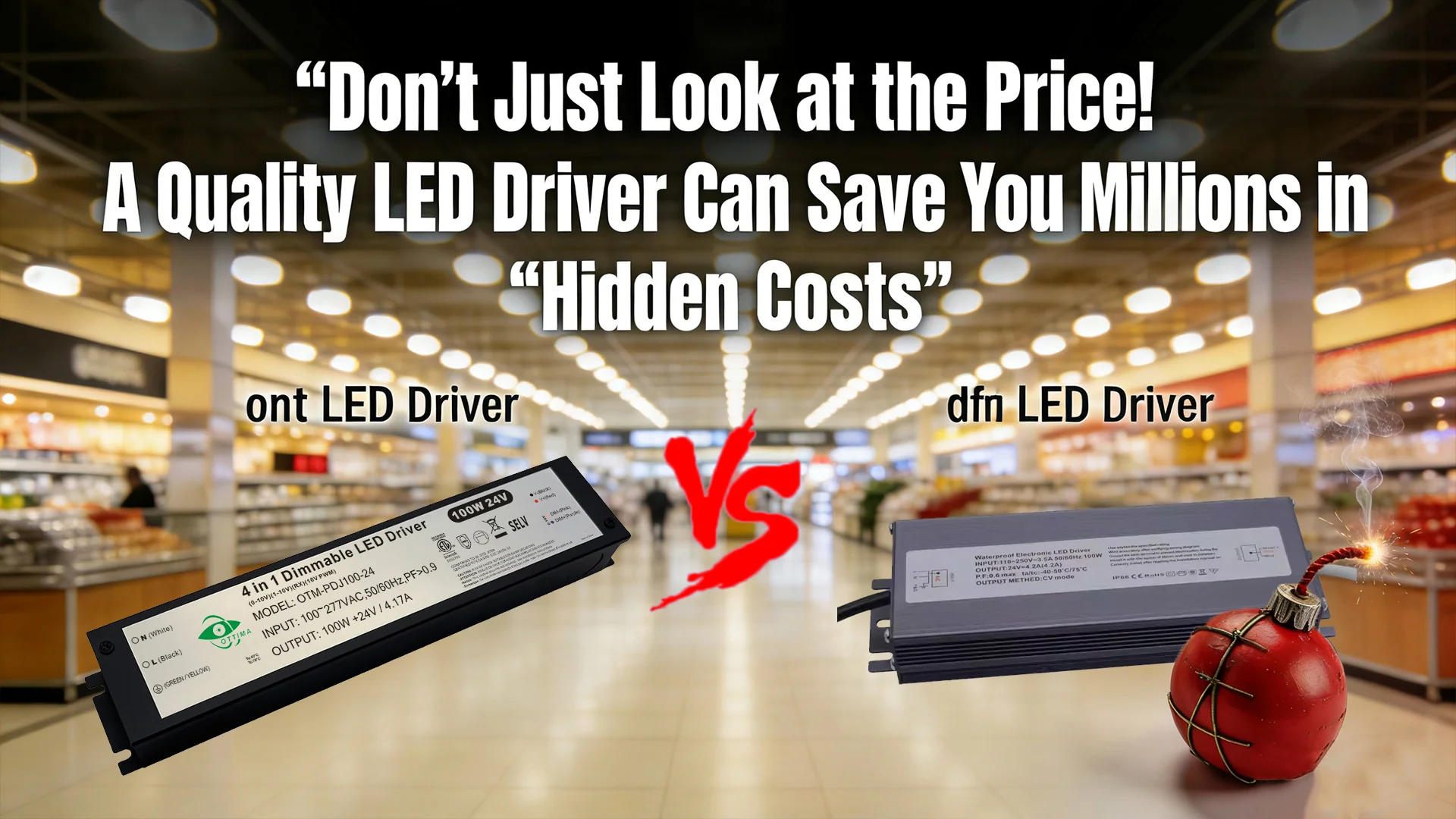

Don't Just Look at the Price! A Quality LED Driver Can Save You Millions in "Hidden Costs"

Friend, have you ever had this experience?

During a project procurement, you found an LED driver priced 20% lower than the market average. You thought it was a great opportunity to save a significant amount on the budget.

However, after the project was implemented, new problems emerged:

A few months later, the lights started flickering and failing frequently, forcing you to spend a lot of time and labor on repairs and replacements.

Complaints from the client piled up, and the project's reputation was tarnished.

Worse yet, during project acceptance, the project failed because the products lacked proper compliance certifications, leading to massive fines and mandatory rectifications.

After all was said and done, you realized that the money you saved initially came back to you in the form of "hidden costs," multiplied.

In the LED driver industry, you get what you pay for. Today, we don't want to talk about empty price wars. We want to talk to you about how a truly quality driver can save you millions in "hidden costs" in ways you can't see, ensuring your projects are safe, reliable, and profitable in the long run.

Your Project Faces Three Major "Hidden Costs"

A low-priced driver is like a beautiful trap. It entices your eyes but hides significant risks. These risks will eventually be converted into your project's costs.

1. Compliance Risk: Millions at Stake Behind a Single Certification

Imagine you have meticulously built a large commercial project, and everything is ready for final inspection. Suddenly, the quality inspection department tells you that because your lighting products do not have the required compliance certifications, the project cannot be approved.

This is a nightmare.

Many low-priced drivers cut corners by forgoing authoritative international certifications such as UL, CE, and CCC. These certifications are not just pieces of paper; they are the "health reports" of product quality and safety, serving as the "passports" for your project to be legally and successfully implemented.

If discovered during project acceptance or market spot checks, you will face the risk of product removal, sales prohibition, and even huge fines. This loss could be several times higher than the total price you paid for all the drivers.

2. Operational Risk: The "Butterfly Effect" of Frequent Failures

A subpar driver is like a ticking time bomb buried in your project. It might work well at first, but its lifespan will be drastically shortened in harsh environments like high temperatures or humidity.

Frequent failures trigger a chain reaction:

Soaring Maintenance Costs: You have to constantly dispatch personnel to the site for troubleshooting and replacements. Labor, travel, and replacement part costs all add up as extra expenses.

Damaged Brand Reputation: Clients will lose trust in your products and services due to frequent lighting failures, which will directly impact your future project opportunities.

A high-quality driver, through the selection of long-life components and strict quality control, minimizes the failure rate. It ensures your lighting system operates stably in the long run, saving you huge operational and maintenance costs while protecting your brand reputation.

3. Safety Risk: The Unseen "Time Bomb"

This is the most critical of all risks.

Inferior drivers often have incomplete or missing protection mechanisms. In the event of abnormal conditions like voltage instability, short circuits, or overheating, they may fail to cut off the power supply in time, leading to:

Equipment Damage: The driver and luminaires could be burnt out, causing direct property loss.

Fire Hazards: Overheating or a short circuit could cause a fire, leading to immeasurable loss of life and property.

A quality driver must have comprehensive protection functions, such as: Over-Voltage Protection (OVP), Short-Circuit Protection (SCP), Over-Temperature Protection (OTP), and Surge Protection. These features act as "safety guards" on duty 24/7, building the final line of defense for the entire lighting system.

How to Choose a Truly "Quality" LED Driver

Stop just looking at the price. Before you make a procurement decision, ask yourself a few questions and pay attention to these key points:

1. Are the Certifications Authentic and Comprehensive?

Don't just look for UL, CE, or CCC logos on the product. Verify that these certifications are authentic and valid, and that they cover the specific applications of your project (for example, outdoor lighting requires different safety certifications).

2. Is the Protection Function Checklist Complete?

Carefully read the driver's specification sheet to confirm it has comprehensive protection functions like over-voltage, short-circuit, over-temperature, open-circuit, and surge protection. These are the foundations of long-term safety and reliability.

3. Evaluate the Manufacturer's Commitment

A reputable manufacturer with a strong track record will offer a long-term warranty and have a complete pre-sales and after-sales service system. They stand by their products because they have confidence in their quality. By choosing them, you are choosing peace of mind and security for your project.

Smart Investment, Continuous Profitability

Friend, today's market is competitive, but the real winners are not those who only fight on price. They are the ones who can provide long-term value and help clients mitigate risks.

Choosing a high-quality, high-safety LED driver is a strategic investment in your project, your brand, and your future. It helps you navigate various risks and turns "hidden costs" into continuous profitability.

Ready to avoid the price trap and choose peace of mind and security? Contact us today, and let's work together to manage the risks and win the future for your project!